Ceramic ion conducting membrane separates gas

The University of Twente in the Netherlands and the Giulic Research Center in Germany are working together to develop membranes that can efficiently separate gases, for example, to produce oxygen or hydrogen.

Ceramic ion conducting membranes are an alternative to existing expensive separation methods and can help reduce carbon dioxide emissions. Professor of Inorganic Membrane at the University of Twente estimates that it will take about five to ten years before a usable technology can be provided.

Carbon dioxide emission

Sustainable energy sources (sun, wind) and more efficient energy use will not be enough to meet greenhouse reduction targets in the coming decades. In order to meet Europe's climate targets, carbon dioxide will also need to be captured and stored, and we are looking at efficient conversion of carbon dioxide to fuel (carbon capture and utilization). Europe's CO2 emissions are expected to be reduced by 15 per cent by 2030.

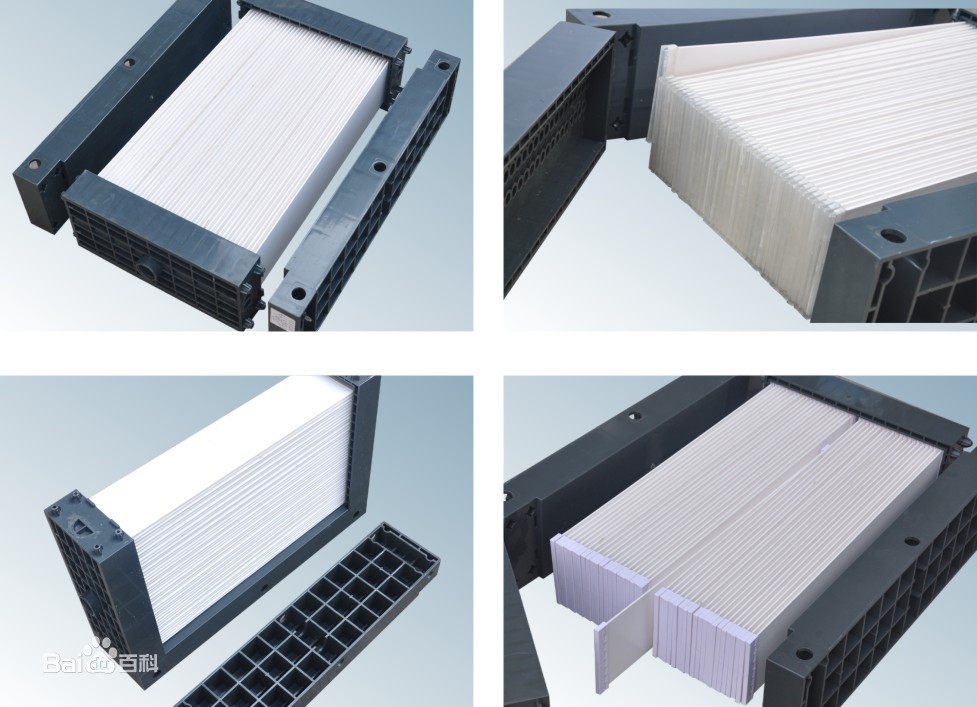

Ceramic ion conduction membrane

Better and more efficient alternatives

Existing techniques for capturing carbon dioxide, such as chemical scrubbing (washing), are expensive and involve a lot of energy consumption. In the process of carbon dioxide neutralization, fuel technology burning with pure oxygen is not a perfect solution for our current level of technology, because producing pure oxygen requires distillation at -190°C, which consumes a lot of energy. A better and more efficient alternative is to use membranes that can separate oxygen. In this way, the fuel can still be burned with pure oxygen, producing a high concentration of carbon dioxide gas. One other possibility is the production of synthetic fuels, developed by the reaction of carbon dioxide and hydrogen gas through membranes.

Cooperation

The University of Twente and the Giulic Research Center have decided to work closely together to develop a ceramic ionic conductive membrane with this goal in mind. These membranes are suitable for membrane reactors that combine the separation process with chemical reactions under extreme conditions (high temperature and pressure) to produce synthetic fuels or base chemicals.

Professor WilhelmMeulenberg, who works at the University of Twente and the Giulic Research Centre, is pioneering research on the new membrane technology. Research at the University of Twente focuses on ceramic membranes for industrial applications. From there, the Giulic research center assemps the membrane reactor with the right components. "The two partners complement each other perfectly," Meulenberg said. "That's why there will be a lot of interaction between PhDs and other researchers at the two institutions in the coming years."

Facebook

Facebook YouTube

YouTube LinkedIn

LinkedIn Twitter

Twitter