New technology of Store hydrogen and make hydrogen

German scientists have developed a new process for storing and producing hydrogen fuel using onboard body fluids and a special catalyst, simplifying the two devices used to load and unload hydrogen fuel into a single device. The new process can greatly reduce the cost and energy consumption, which is of great significance to the energy transformation.

One of the most efficient ways to use renewable energy is to make hydrogen by electrolysis of water, which is then stored for later use. Efficient hydrogen storage technology has always been a key issue for scientists all over the world. In the latest study, scientists at the Uhrlich Research Center's Institute for Renewable Energy and the University of Erlangen-Nuremberg combined hydrogen fuel with a special onboard body fluid to form a stable chemical that allows hydrogen fuel to be stored safely and transported easily. The storage and release of hydrogen fuel is a reversible chemical reaction, which takes different steps and requires a special catalyst for each reaction, said Josik, an expert at the Ulich Research Center.

In order to let two device 2 for one, the researchers developed a special kind of catalyst, it can make the loading and unloading of hydrogen fuel effective catalytic reaction under the same temperature, therefore, in a device, change the pressure of the hydrogen fuel can be completed storage and release, greatly simplifies the hydrogen storage requirement for equipment, can save 30% to 50% of the equipment cost.

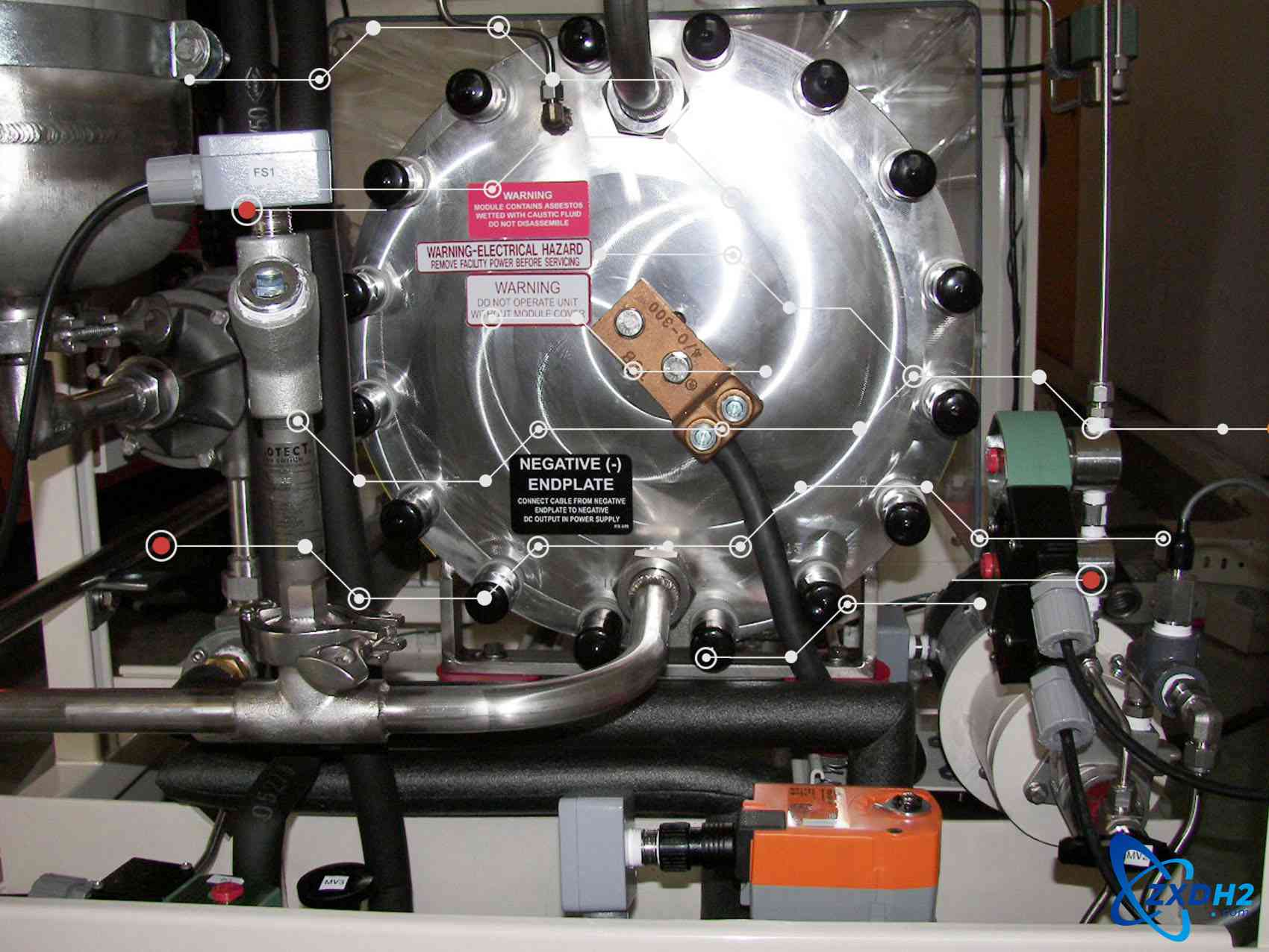

Hydrogen production, storage and hydrogenation system

Another benefit of the new process is that it makes full use of the heat generated by the chemical reaction when the stored hydrogen fuel is released. According to Josik, hydrogen fuel storage facilities currently operate at temperatures of about 150 degrees Celsius. The hydrogen fuel release facility operates at a temperature of about 300 degrees Celsius. Although it is theoretically possible to use the heat of reaction from hydrogen fuel storage for release, this is difficult to do because of the different chemical reaction temperatures of the two devices. The new process, which stores the hydrogen fuel at higher temperatures, produces heat that can be used directly when it is released. For this reason, the researchers have also developed a high-temperature hydrogenation process, along with a corresponding catalyst.

, experts say, compared with the currently used to separate hydrogen fuel device, this integration is the main benefit of hydrogen fuel plant, hydrogen storage and production will be very convenient, for storage and for making hydrogen fuel was beneficial to industrialized production, the solar wind sufficiently smooth and safe use is also useful, will in the future of renewable energy in the system.

Facebook

Facebook YouTube

YouTube LinkedIn

LinkedIn Twitter

Twitter