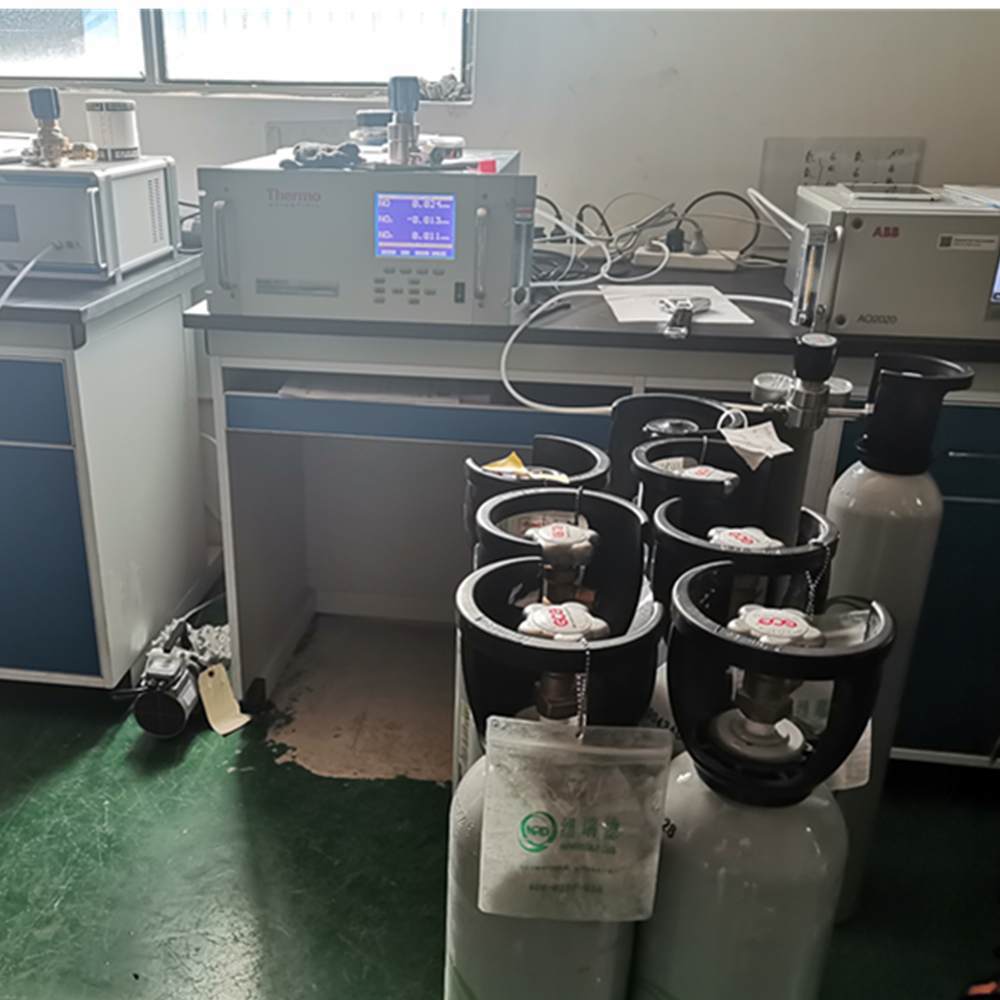

Storage of oxygen standard gases and nitric oxide

This method is a method for stably preserving the composition of nitric oxide or oxygen standard gases. More specifically, a waxed high pressure vessel is filled with these standard gases to keep its composition stable.

In order to detect atmospheric pollution, an analyzer is used to measure harmful gases in the atmosphere. However, these analyzers do not measure absolute values in principle, but rather the general measurement of comparison with standard gases to calibrate the analyzers before each measurement or at regular intervals with standard gases. Therefore, in order to obtain accurate analysis results, it is necessary to have a standard gas whose composition is accurate and which remains constant for a long time.

Based on this method, it is expected that the concentration of the standard gas will change little over a certain period of time. However, due to the strengthening of regulations to prevent air pollution, concentration determination is moving to lower concentrations. In addition, the more reactive gases such as nitric oxide and oxygen, the lower the concentration of the standard gases, the greater the variation in their composition.

Repeated studies on the reasons for the change of nitric oxide standard gas or oxygen standard gas with time in high pressure vessels have shown that, in addition to impurities such as water (water vapor) in feed gas (constituent gas and dilute gas), this is mainly caused by the reaction or adsorption of standard gases such as oxygen with the vessel wall.

Detection and storage

Therefore, in order to prevent the standard gas direct contact with the inner wall of the container, will be difficult to react with the standard gas and difficult to adsorption material coated on the inner wall of the container, which can make the standard gas for a long time constant, steady its concentration For this purpose, the coating for a variety of research results show that the container waxed can maintain long-term stability standard gas.

This method is a method of filling nitric oxide standard gas and oxygen standard gas into a high pressure vessel coated with wax to keep their composition stable. The coating is in gallo wax, cantley tree wax, wax, wax, paraffin wax, pure natural wax, wax and cabo, silicon carboxyl wax, Mr. Baxter wax, polyethylene wax, synthetic wax: choose a or have to use all kinds of standard gas preservation methods are: on the inner wall of the high pressure vessel, gold-plated, nickel and other metals, with fluorine resins such as plastic coating, high pressure gas container wall polishing, filling in advance is a high concentration of ammonia oxidation or oxygen adsorption equilibrium processing methods. However, the processing cost of the gold-plated method (raw material cost, equipment cost, labor cost) is high, and it is difficult to complete the base cover, easy to produce pores, so there are errors between containers. Secondly, in addition to the high production cost of plastic coating, gas is easy to adsorb on the plastic film, causing the concentration to change with time, and the coating is easy to fall off from the inner wall of the high-pressure container. And within the

The force method of wall polishing and adsorption equilibrium treatment makes the error between the vessels easy to occur. The concentration of the vessels treated by this method will change at any time when filling the standard gas, although it is much better than that without treatment, it is difficult to obtain the standard gas with complete barrier stability.

On the contrary, the wax is heated to dissolve and the liquid wax is evenly applied to the inner wall of the container. Because the coating is dense, it is difficult to produce pores and do not absorb gas. In addition, the method has the advantages of simple processing, low price and small error between containers.

Facebook

Facebook YouTube

YouTube LinkedIn

LinkedIn Twitter

Twitter