Static gas distribution technology for quasi - gas

Static distribution of standard gases is to add a certain amount of liquid or feed gas to a container of a known volume of diluted gas and mix it evenly. The concentration of the standard gas can be calculated according to the amount of the added liquid or feed gas and the volume of the container. The commonly used static gas distribution technology is as follows:

1. Syringe gas distribution method

It is very convenient to use syringe to distribute air for work with small amount of air. Take two syringes of different sizes. The large syringe is usually 100ml, while the small syringe depends on the distribution of air. With gas, put a small pieces of metal in the syringe, pushes the piston into the, again with a small syringe to take a certain amount of raw material gas, connect the two syringe in figure 2, the small syringe gas into the syringe, remove the small syringe and rubber cap, twitch syringe piston, with clean air gas will be diluted to 100 ml, shake syringe in sheet metal, make the gas mixing, You get a lower concentration of the standard gas. The concentration after dilution can be calculated from the volume of gas before and after dilution. If a dilution can not meet the requirements, but also for the second time, the standard of gas static although distribution technology has simple equipment, easy to operate, the advantages of but because of its low gas distribution, and take in the process of the gas concentration changes, so the air demand larger or ventilation is not adapted to the work, for a longer time to dynamic distribution technology standard gases preparation.

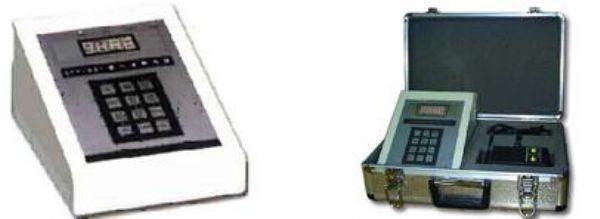

Static gas distributor

2. large bottle gas distribution method

The glass bottle or polyethylene plastic bottle with large volume is cleaned and dried, and then filled with clean air to replace the original gas in the bottle, then pumped into negative pressure, and then filled with a certain amount of liquid or raw material gas. If the raw material is a gas at room temperature, add it with a gas ration pipe (see Figure 1) and fill it with clean air to normal pressure. If the raw material is volatile liquid, a certain amount of liquid can be weighed in a small ampere bottle, put into a large bottle, and pumped to make the bottle negative pressure, and then shake the bottle to pieces. After the liquid volatiles, clean air is added to the normal pressure.

The actual concentration of the standard gas is often lower than the calculated value when the gas is distributed in a large bottle due to the adsorption of the wall. In order to avoid this effect, the first good gas can be placed for a period of time and then removed, and then the second gas distribution. This can reduce the adsorption of the bottle wall. If a lower concentration of gas is needed, it can be diluted by vacuuming after gas distribution in a large bottle. For example, a gas in a large bottle can be pumped to half its original pressure and then filled with clean air at the same pressure to produce a standard gas of half its original concentration.

Facebook

Facebook YouTube

YouTube LinkedIn

LinkedIn Twitter

Twitter