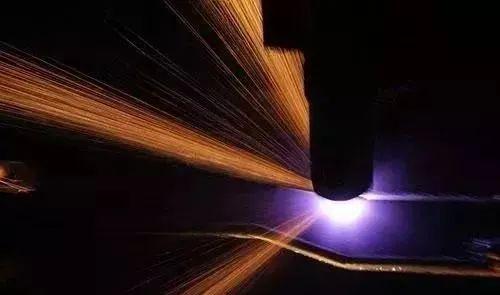

He, Ar gas laser welding applications

There is an urgent need for speed in the current competitive automobile market. For their part, consumers are more concerned about horsepower. In manufacturing, however, speed is what volume and productivity are all about. American carmakers are losing market share for a number of reasons, including body design, perceived quality and cost of ownership.

While discussion of body design is outside the scope of this article, strategies for improving quality and productivity are the focus. Both can be achieved through hybrid machining technology, which combines laser welding with conventional metal electrode gas arc welding (GMAW).

Laser parameters such as wavelength, beam quality, spot size, power density, depth of focus, and beam positioning are critical for successful welding. Other parameters include the conventional replenishment and pulse transmission of the GMAW energy source, the positioning of the GMAW wire, the Angle of contact, and the chemical properties of the wire. In addition, the oxide surface condition of the substrate material, the design of the joint, the width of the weld, and the type and flow rate of the shielding gas also affect the quality and performance of the hybrid welding process.

The effects of gas selection on many aspects, including laser beam interaction, protection efficiency, bead performance, and the equipment used to transfer standard gas mixtures and flow rates, will be described in detail below.

Hybrid laser processing technology incorporates a secondary energy source into the weld pool area. Hybrid machining technology has been able to materialize the advantages of laser welding, including increased welding speed, limited heat affected zone, narrow welded joints and superior bead profile. As a secondary energy source, GMAW improves the overall process energy efficiency, reduces equipment costs and increases the ability to weld gaps. In addition, it reduces cooling rates and improves the energy coupling efficiency of aluminum.

Gas laser welding technology

Second, although the equipment is more complex, by reducing the size of the cavity needed to perform the welding, the power supply cost of the GMAW is reduced, thus reducing the overall cost of the machine. Depending on the desired results, the position of the GMAW wire feed can be determined before or after the laser beam. Higher welding speed can be achieved by using the trailing GMAW wire feed mode. The GMAW wire is fed into a laser-generated fusion pool, so the secondary energy needed to melt the wire is reduced.

In addition, when the filler wire reaches the tail, the GMAW's arc produces plasma that vaporizes the base material, resulting in a depression at the front edge of the pool. This depression in the molten weld pool reduces the total depth through which the laser beam must penetrate, thereby improving penetration. It has been well documented that vapor particles expelled from the keyhole or welding area cause attenuation (scattering and absorption) of the laser beam, thereby reducing the beam energy coupled to the substrate material. The scattering and absorption of laser beam reduce the speed and depth of welding. 2 The adhesive layer determines that the larger the particle is, the more serious the attenuation effect will be.

The helium shielding gas brings the smallest average vapor particle size. This indicates that pure helium is the best choice for controlling particle size for CO2 or YAG laser welding. We must admit that helium does have a higher ionization rate and a lower plasma formation voltage than argon, but its molecular weight is lower. Therefore, helium gas needs a high flow rate to effectively expel the metal vapor from the path of the laser beam. Because helium has a higher unit cost than argon, this increases the average cost per foot of welding.

Information on helium and argon

Facebook

Facebook YouTube

YouTube LinkedIn

LinkedIn Twitter

Twitter