Standard for argon welding of aluminum alloys (1)

Aluminum welding method: almost all kinds of welding methods can be used for welding aluminum and aluminum alloy, but the adaptability of aluminum and aluminum alloy to various welding methods is different, each welding method has its own application occasions. Gas welding and electrode arc welding, simple equipment, easy to operate. Gas welding can be used to repair welding of aluminum sheet and castings with low welding quality requirements. Electrode arc welding can be used for repair welding of aluminum alloy castings. Inert gas shielded welding (TIG or MIG) is the most widely used welding method for aluminum and aluminum alloys. Aluminum and aluminum alloy sheet can be welded by AC argon arc tungsten welding or pulse argon arc tungsten welding. Tungsten-helium arc welding, argon-helium mixed tungsten gas shielded welding, fusion gas shielded welding and pulse fusion gas shielded welding can be used for aluminum and aluminum alloy thick plates. MGW and pulse MGW are widely used (argon or argon/helium mixture).

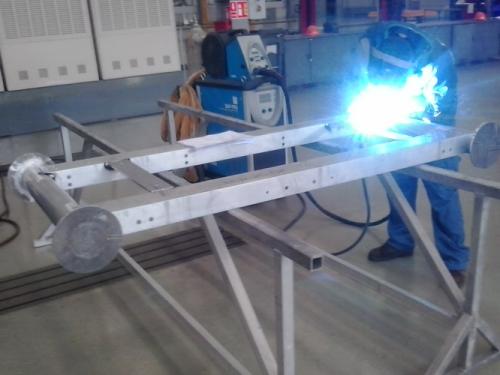

Aluminium alloy welding

Weld preparation

1. Cleaning before welding:

When welding aluminum and aluminum alloy, the oxide film and oil on the welding joint and the welding wire surface should be strictly removed before welding.

1) Chemical cleaning Chemical cleaning efficiency is high, stable quality, suitable for cleaning welding wire and small size, batch production of the workpiece. There are two kinds of dipping and scrubbing. Acetone, gasoline, kerosene and other organic solvents can be used to remove oil on the surface, and then 5%-10% NaOH solution at 40℃ ~ 70℃ can be used for 3min ~ 7min alkaline washing (for pure aluminum, the time is slightly longer but no more than 20min), followed by 1min ~ 3min pickling with 30%HNO3 solution at room temperature to 60℃, and then washed with flowing water, air drying or low temperature drying.

2) mechanical cleaning: mechanical cleaning is often used when the workpiece size is large, the production cycle is long, and the multi-layer welding or chemical cleaning is stained. First with acetone, gasoline and other organic solvents to wipe the surface in order to remove oil, then directly with a diameter of 0.15mm ~ 0.2mm copper wire brush or stainless steel wire brush, brush to expose the metallic luster. It is generally not suitable to use grinding wheel or ordinary sandpaper to grind, so as to avoid sand particles remaining on the metal surface and slag inclusion and other defects when welding into the molten pool. In addition, scraper and file can also be used to clean the surface to be welded.

Facebook

Facebook YouTube

YouTube LinkedIn

LinkedIn Twitter

Twitter