Information about n-butene (1)

Preparation method:

In industry, it is mainly obtained by the separation of carbon four fractions. The content (quality) of butene in the four fractions of carbon from different sources is different. The C4 fraction obtained from FCC contains about 13% 1-butene, 12% cis-2-butene and 13% trans-2-butene. About 14% of 1-butene, 5% of cis - 2-butene and 6% of trans - 2-butene are found in C4 fraction. When separating the isomers of butene by C4 fraction, butadiene and isobutene are generally separated first, and then rectifying (or isomerization, adsorption, etc.) of the remaining materials can be obtained, and the purity of 1-butene is higher than 99%. Butene in some chemical applications (such as water synthesis of secondary butanol) three isomers can be used as raw materials, butane, isobutane as inert and do not affect the reaction. Therefore, in these cases, separation between butenes, butene, n-butane and isobutane is not necessary.

In addition, there are several ways to synthesize 1-butene or 2-butene. If in the presence of titanate (butyl ester or aromatic ester) and triethyl aluminum, make ethylene dimerization reaction, can obtain 1-butene. A considerable amount of 1-butene is also produced when ethylene is oligomerized under the action of nickel catalyst to produce long-chain α-olefin. When propylene is disproportionated, ethylene and 2-butene can be produced. This method was used in industrial production, but has been discontinued at present.

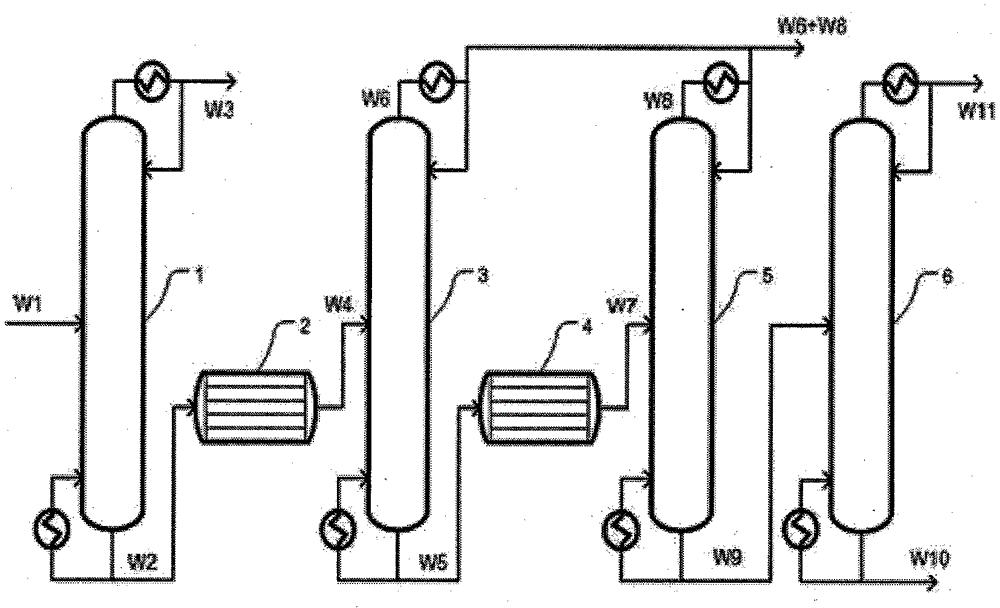

Fraction separation

Safety risks:

All isomers of butene have similar toxicity and belong to low toxicity class. Toxicity is similar to other alkenes, but lower than pentene and 4.5 times greater than propylene, mainly due to simple asphyxia, weak anesthesia and weak stimulation. Liquid butene can cause skin frostbite.

Facebook

Facebook YouTube

YouTube LinkedIn

LinkedIn Twitter

Twitter