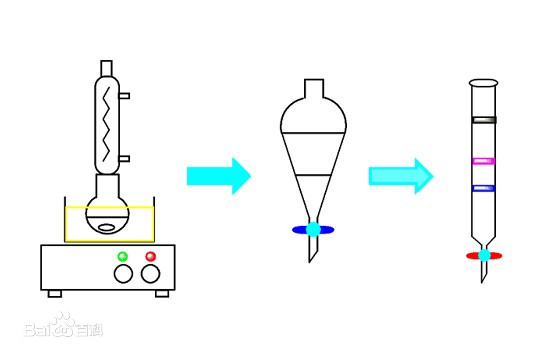

The simple overview of CO transform

The transformation of carbon monoxide refers to the process in which the gas reacts with water vapor under a certain temperature with the help of a catalyst, and carbon monoxide generates carbon dioxide and hydrogen. The carbon monoxide in the gas was removed by the transformation reaction, and the effective gas hydrogen for methanol production was obtained. Therefore, the change section is not only the transformation process, but also the purification process.

In the gas from the former section, the content of carbon monoxide is high. After the transformation reaction, the CO/H2 in the process gas is required to be about 2.05~2.1, so as to meet the requirements of methanol synthesis.

Gas-solid phase catalytic reaction

Carbon monoxide conversion reaction is a typical gas-solid phase catalytic reaction, which is carried out in the presence of catalyst. Widely used in the '60 s, before shift catalyst Fe - Gr catalyst, using temperature range is 350 ~ 550 ℃, the' 60 s, cobalt, molybdenum catalyst hydrogenation process is developed and zinc oxide desulfurizer, and the operating temperature is 200 ~ 280 ℃, catalyst to distinguish these two kinds of different operating temperature transformation process, habits, the former is called "medium temperature transformation", which is called "low temperature shift".

According to the heat recovery method is different, can be divided into the chilling transformation process and the waste heat boiler, cold shock in the process of cold shock after the crude feed gas has been saturated with water vapor, under the condition of without cooling and desulfurization directly transform, as a result, two kinds of process according to the process conditions of different choose different catalysts, quench process using Co - Mo sulfur resistant shift catalyst, waste heat boiler the Fe - Cr shift catalyst

Facebook

Facebook YouTube

YouTube LinkedIn

LinkedIn Twitter

Twitter