Method and conclusion of CO generation (1)

Carbon monoxide (CO) is a widely used chemical base material. In recent years, with the development of C chemistry, carbon monoxide as raw material of various reaction increases, which greatly promoted the synthesis of carbon monoxide research. In order to meet the market demand for high purity and low cost ~ carbon oxide, scientists in China and other countries have done a lot of work in this field and achieved gratifying results. There are many synthesis methods of carbon monoxide, but the methods suitable for the production of high purity carbon monoxide are summarized as follows: liquid sulfuric acid catalytic dehydrating method, charcoal dry ice high temperature reduction method, solid acid catalytic dehydrating method. Each of these valuable production methods has its own advantages and disadvantages, which are discussed in the following sections.

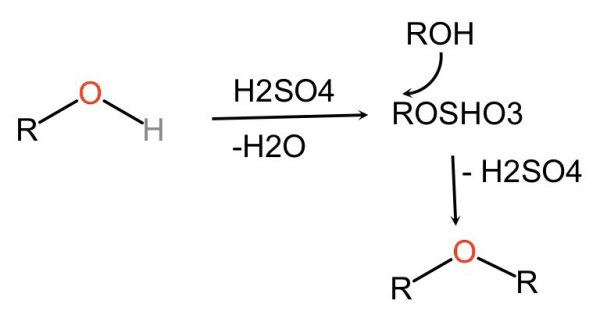

Catalytic dehydrating of concentrated sulfuric acid

This is a classic but very mature practical method. The advantages of this method are that the carbon monoxide produced is of high purity and the conversion rate of formic acid is good. It is suitable for both small-scale and industrial production of carbon monoxide. Guangming Chemical Research and Design Institute of the Ministry of Chemical Industry adopted this method for large-scale production research as early as the 1980s. Syngas by gas chromatography analysis: H 0.2 ~ 0.4, O2200 ~ 800× 10, N2100 ~ 400×10, C0 30 ~ 100×10 and trace methane and steam (below 80℃ saturated water content). The content of carbon monoxide was more than 99.99 after multistage adsorption purification of syngas. The disadvantage of this recipe is that the concentration of H SO used. , formic acid to equipment, pipelines, valves, instruments and other serious corrosion, suitable for concentrated H SO. The material is not suitable for dilute sulfuric acid (concentrated H SO when reacting. Drops in concentration, thinning), formic acid. And the H SO formed during the reaction. The corrosion of HC0OH - H 0 element system is more complicated. Experience shows that even for stainless steel (1CrL8N 9Ti) devices, the wall thickness will gradually thin after a short time of use, eventually leading to the device scrap, but also buried the hidden danger of insecurity. In order to avoid the strong corrosion of the material to the equipment, the enamel glass reactor is mostly used in industry. In addition to the above disadvantages, another disadvantage of this process is that the reaction produces a large number of dilute H with a certain concentration of CO. SO. (the acid concentration is 60 ~ 70), if not properly used, these waste acids will seriously pollute the environment, and because carbon monoxide is flammable, explosive and highly toxic, it will lead to the threat of personal security. In addition, due to the formation of water in the reaction process, the catalyst concentrated sulfuric acid gradually becomes thinner and its dewatering capacity decreases continuously.

Principle of catalytic dehydration with concentrated sulfuric acid

The rate of carbon monoxide production decreases by several times. If concentrated phosphoric acid is used instead of concentrated sulfuric acid, the same effect can be achieved, but the cost is higher than concentrated sulfuric acid. Substituting oxalic acid for formic acid produces carbon dioxide of the same volume as carbon monoxide, which makes purification difficult.

Charcoal dry ice high temperature reduction method

The reaction of this method is as follows:

The main reaction is C+C0 2CO + L73.2KJ/MO1

Adverse reaction Co +H - CO+ He

2C+2H2 -CH.

Under high temperature hot coke or charcoal with carbon dioxide reduction reaction, carbon monoxide. This is an endothermic reaction, which requires external heat for the reaction to proceed. When the amount of production is not large, the tubular silicon carbon tube high temperature heating furnace can be used, the reaction tube can use stainless steel tube wall thickness. However, because the reaction is carried out at high temperature, and every day needs to rise and cool, so, the heating furnace wire is often brittle broken, at the same time, the stainless steel tube is very easy to soften and burn through at high temperature, very unsafe. At present, all domestic steel pipes can not withstand this high temperature for a long time, and the price of this imported high temperature resistant stainless steel pipe is quite expensive, and not easy to use with domestic materials. Based on the domestic conditions, Lanzhou Institute of Chemical Physics, Chinese Academy of Sciences adopted this process. First, the tubular reactor was used for small-scale production, and finally, it developed to the large-scale production of the electric arc furnace with high automation degree and rapid cooling and heat resistance.

Facebook

Facebook YouTube

YouTube LinkedIn

LinkedIn Twitter

Twitter